-

NEW CHROME SUBMICRON CARBIDE INSERTS FOR WOODWORKING

The Science Behind 2X Insert Productivity Gains

Stock List Insert Knives Catalog Profile Blanks Catalog Terminus Carbide Knives Available Insert Grade Sheet Ceratizit Carbide MSDS

View The KCR08 Performance Chart

Featured in National Hardwood Magazine

Carbide insert wear apparent in woodcutting is created by a large percentage from chemical corrosion with the carbide’s cobalt binder (glue). This allows the hard tungsten particles to leach out thus creating a dull cutting edge.

How does Corrosion Happen in Wood?

During woodcutting resins, tannins, sap, moisture and also various glues present in wood today create an acidic environment that chemically attacks the carbide surface, leaching the cobalt binder away. This chemical leaching process is enhanced with higher cutting temperatures.What’s in the Red Box? Ceratizit® CHROME KCR08

What is Chrome Submicron Binder KCR08?

CERATIZIT have created a revolutionary new corrosion resistant Chrome binder grade called KCR08. Submicron chrome replaces cobalt as the primary binder.Submicron Chrome is Resistant to Corrosion Resulting in up to Two Times the Cutting Life.

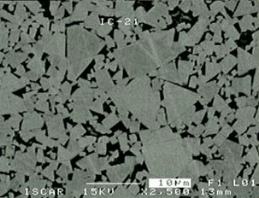

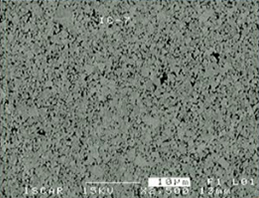

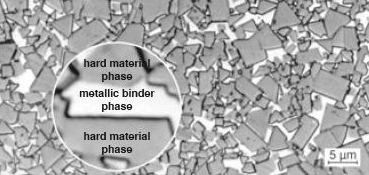

KCR08 also incorporates a submicron grain structure, this means the tungsten particles (tungsten is what makes carbide hard) are much smaller than conventional carbide, so when the tungsten does finally release from the binder it has a much smaller impact to the cutting edge as smaller pieces of tungsten are being removed.Standard Substrate Above 1 Micron

Submicron Substrate Below 1 Micron

Three Major Benefits of Chrome KCR08:

1. Greater Corrosion Resistance

Corrosion to conventional carbide inserts can be caused during tool fabrication from grinding lubricants and also during wood cutting from chemicals/resins/glue and air moisture result in premature tool wear. This also reduces the component cut surface quality.Chrome KCR08 grade minimizes these risks during tool manufacturing as well as during the operation of the finished tool. Your process becomes more stable; machining times are optimized, with an overall performance improvement of the finished tool of up to two times.

2. Higher Performance Potential

For wood working applications, KCR08’s optimized binder system improves the ratio of hardness vs. fracture / impact toughness. Compared to conventional grades, KCR08 grade at same hardness is tougher and therefore more resistant to impact. The cutting edge has greater stability and will resist chipping longer. This will allow the tool producer to use harder grades than previously used conventional grades due to the improved toughness and chipping resistance. The results being better tool life time at improved cut quality.3. Cost Effective

Prices for KCR-grades are at a comparable level to those of our current conventional grades. Higher process reliability and increased cutting performance of up to two times will enable process cost savings and provide you with an enhanced price-performance ratio.Submicron grain size in conjunction with Chrome is a very important part of what makes KCR08 perform the way it does. Submicron means the size of Tungsten particles (grain size) in KCR08 are much smaller than Micron. When tungsten particles do finally release from the cutting edge through wear there are much smaller tungsten particles being removed from the knife compared to larger chunks of Tungsten with Micrograin.

CERATIZIT - A Passionate Pioneer in the Hard Metal Industry

For over 90 years, CERATIZIT has been a pioneer developing hard material solutions for cutting tools and wear protection. The family owned company, headquartered in Mamer, Luxembourg, develops and manufactures highly specialized tungsten carbide cutting tools, carbide inserts and rods. CERATIZIT is the market leader in several wear part application areas and develops successful new types of hard metal grades used in the wood and stone working industry.

With over 5,300 employees at 22 production sites and a sales network of over 50 regional offices, CERATIZIT is a global player in the hard metal industry. The leader in material technology is continuously investing in research and development and holds over 600 patents.

Innovative hard metal solutions from CERATIZIT are used in machine and tool manufacturing and many other applications including automotive, aerospace and oil and gas. The internationally recognized group also includes the brand WNT, the joint venture partnerships with Günther Wirth and CB-CERATIZIT, as well as the Californian tool manufacturer PROMAX Tools.

To connect with a distributor for Chrome Carbide Inserts, contact us.