GRASCHE USA's Custom Circular Saw Plates Deliver Cutting-Edge Quality

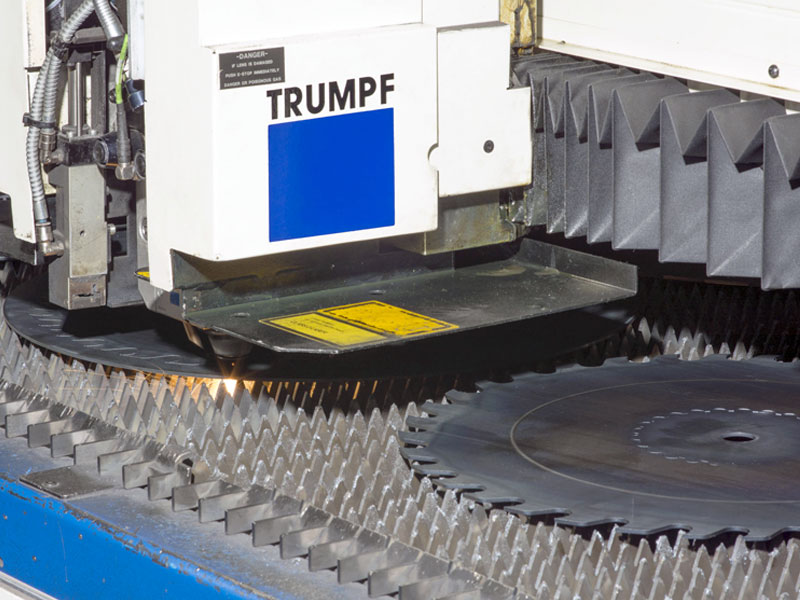

All GRASCHE USA custom circular saw plates are laser cut, annealed, ground, reamed and individually hammered and tensioned by our highly trained and experienced saw smiths, who have over 75 years of combined experience.

- High Accuracy Trumpf CNC Lasers

- CNC Surface Grinding Machines

- RMS Finish Inspection

- Countersinking

- ARKU Flattening

- CMM Optical Inspection

- Annealing Ovens

- Highly Experienced Hammersmiths

- 3 and 4 Axis CNC Machine Centers

- Wide Belt Sanding - De-Burring

- CNC Tension Rolling

- CAD CAM Design Services

- Diameter:

Min: 3" (76.2mm)

Max: 41" (1,041mm) - Thickness:

Min: 0.020" (0.5mm)

Max: 0.255" (6.5mm) - Hardness:

Min: 32RC

Max: 48RC

Sandblasted Seat Pockets:

Standard up to 24" diameter

Bores:

Reamed to H7 tolerance for all popular US and metric diameters

Laser bore H8–H10 tolerance available for any diameter at lower cost

Keyway:

Round, square or custom

Thin Rim-Hubbed:

Single and double hub

Pin Holes:

Straight and countersunk

Finish Polish Grind:

20Ra or better finish

Laser Slots:

Available with copper, open, laser or custom

Seat Pockets:

We can cut pockets for all US and metric-style carbide tips, PCD or no pocket for stellite

Double Annealed:

"Blue plate" also available

Lead Time for Saw Plates:

10-12 working days for 3"(76.2mm) -24" (609mm)

15-17 working days for 24.1" (610mm) - 41" (1,041mm)

Rush Orders:

We offer a 3-day rush service at a premium price, raw material permitting

Precision ground available at additional cost and delivery time